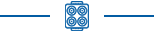

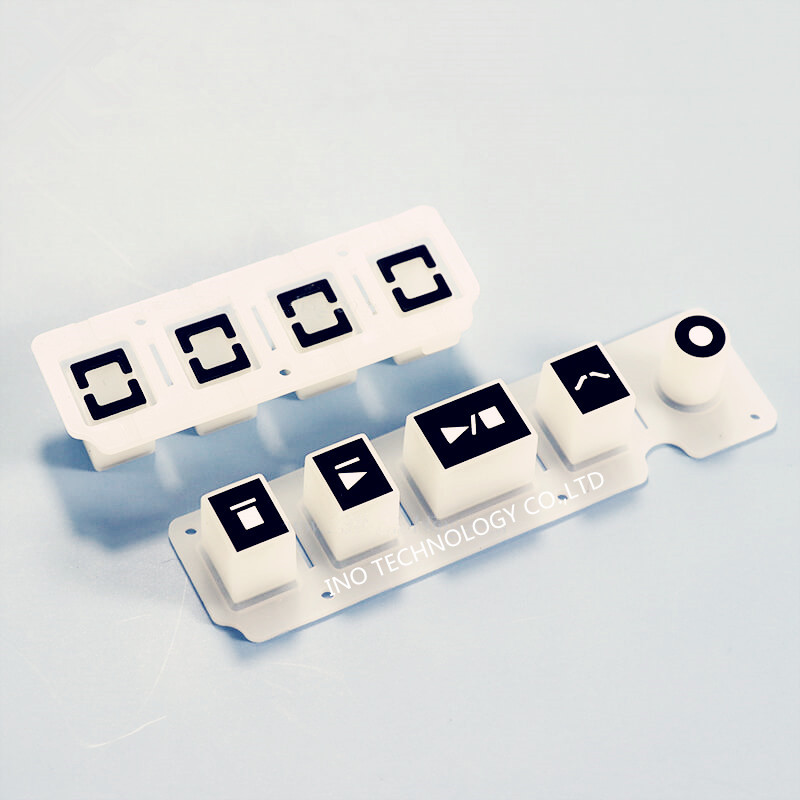

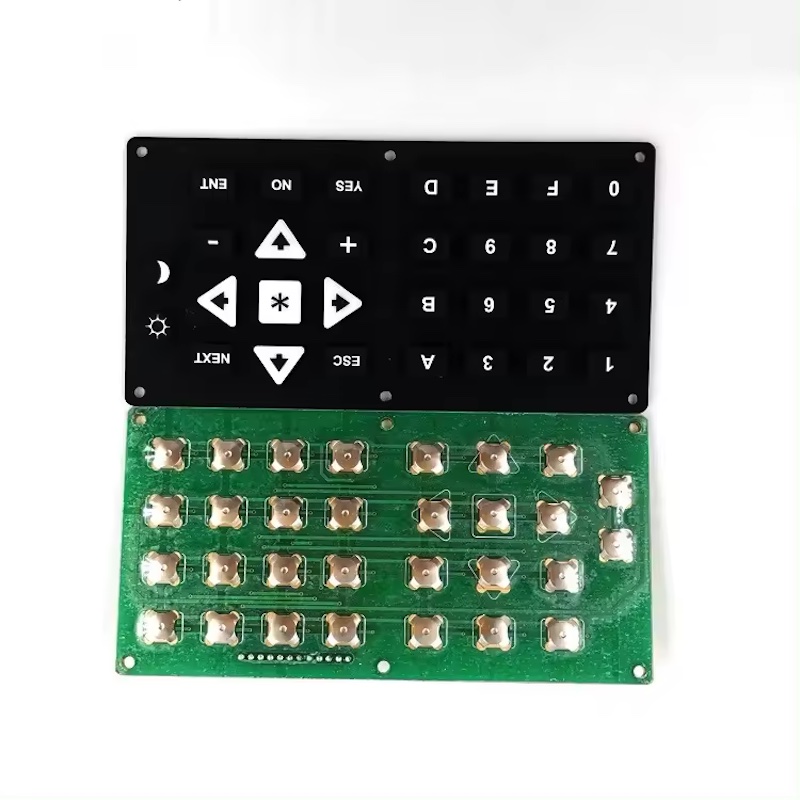

- Teclado de interruptor de membrana

- Sobreposição gráfica

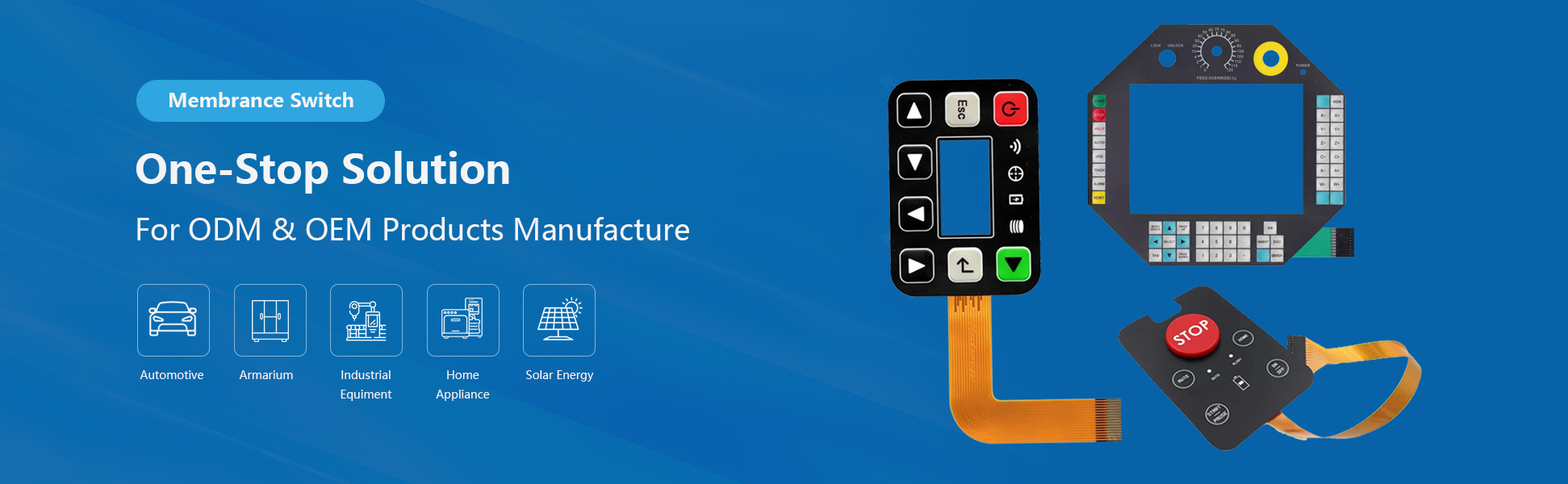

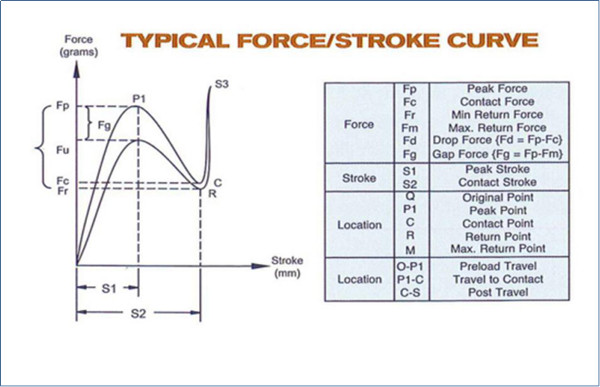

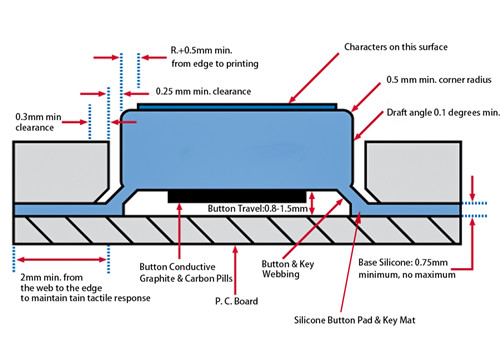

- Interruptor de membrana

- Cúpula de metal do interruptor de membrana FPC

- Monitor TFT de interface RGB de 50 pinos

- Peças de injeção IMD

- Tiras de vedação de borracha para automóveis

- Peças plásticas de injeção de cores duplas

- Ganchos para telha solar fotovoltaica

- Bomba de água

September 18, 2020

September 18, 2020